Automated Insert Placement

Sponsored by Safran Aerospace

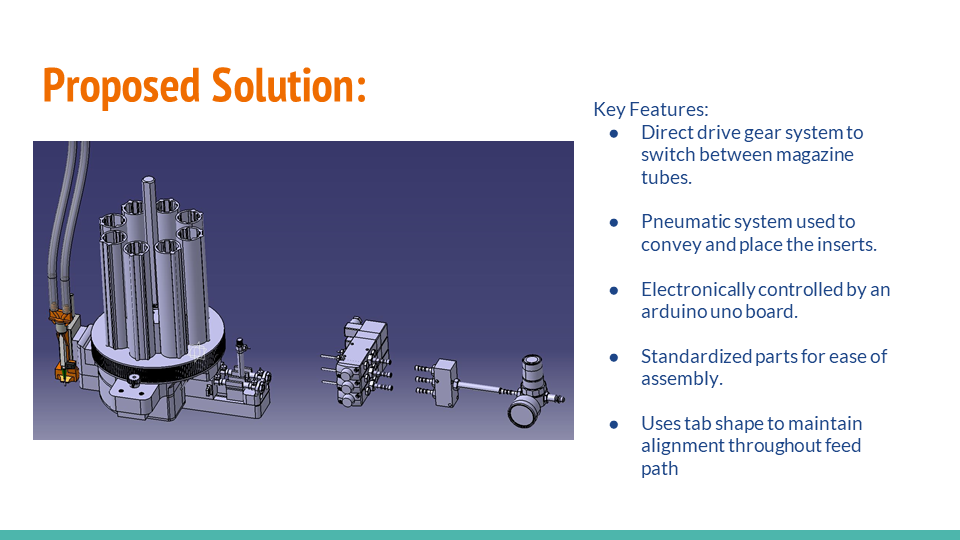

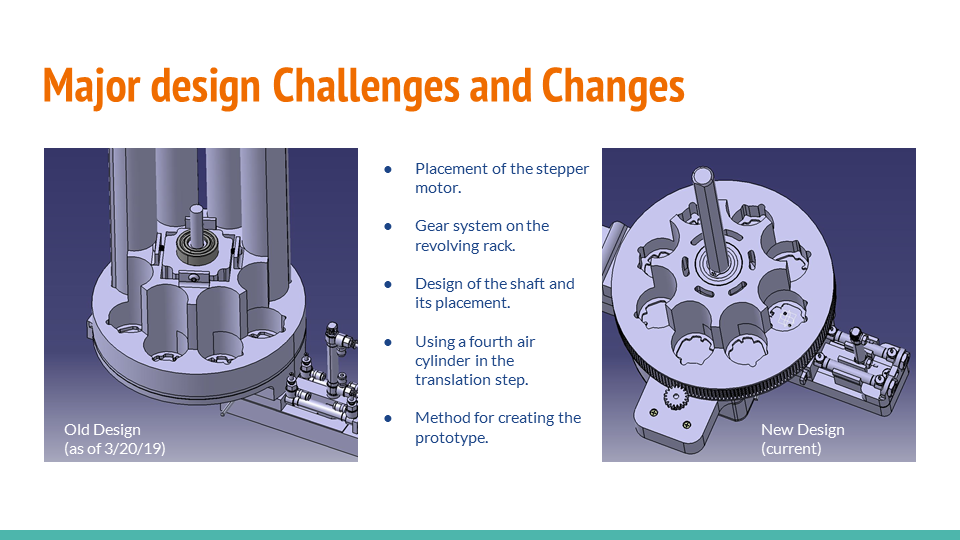

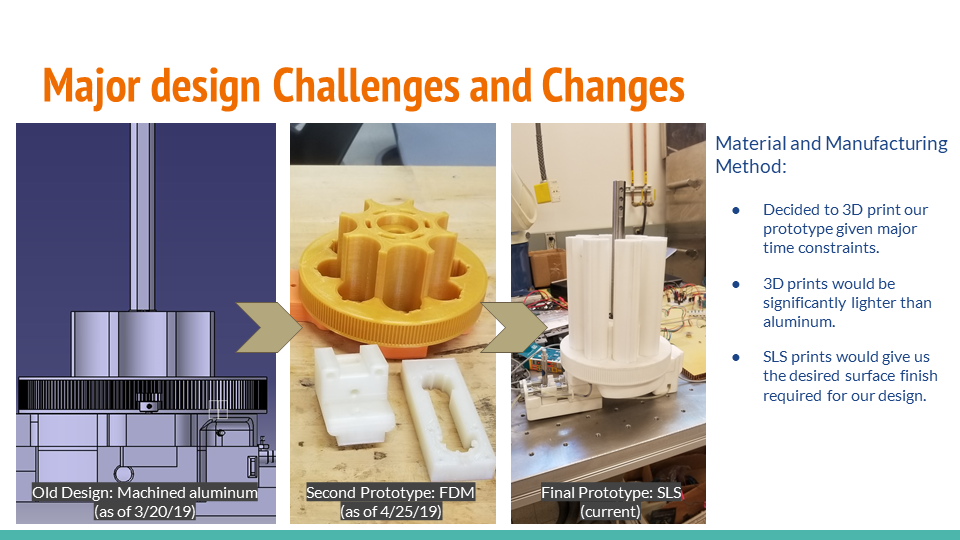

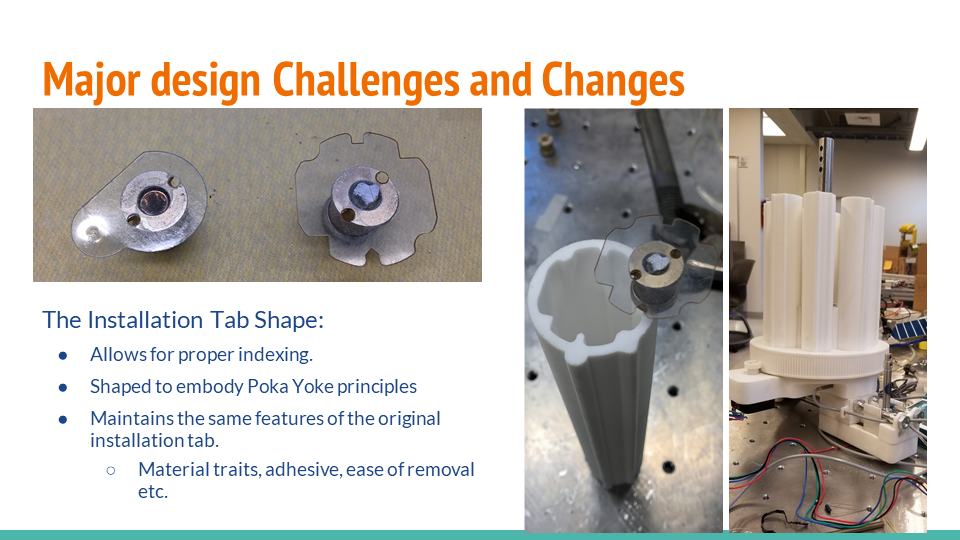

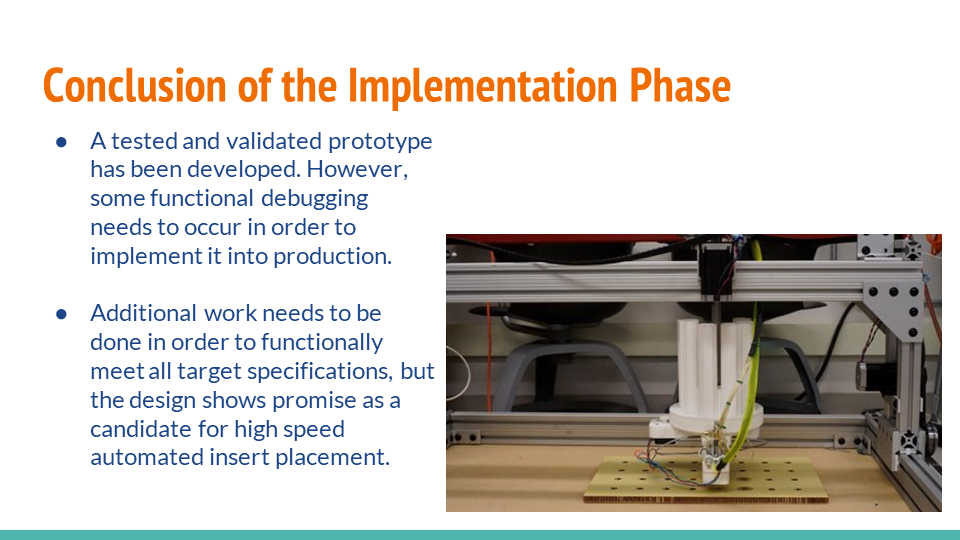

For my senior project for my manufacturing program at Western Washington University, I worked as design lead and on a team collaborating with Safran Aerospace to create an automated insert placement system. The purpose of the created device is to place threaded inserts into panels so that the panels can be assembled to build up aircraft cabin interior components such as bulkheads, lavatories, and overhead storage bins. My place on the team was to design all physical components of the system. Embedded below is a 3d rendering of the file that I have created.

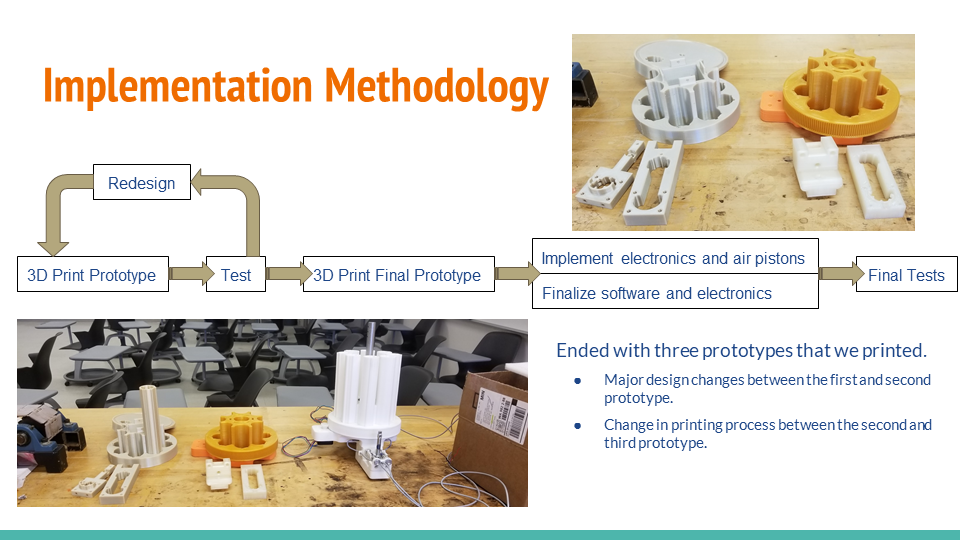

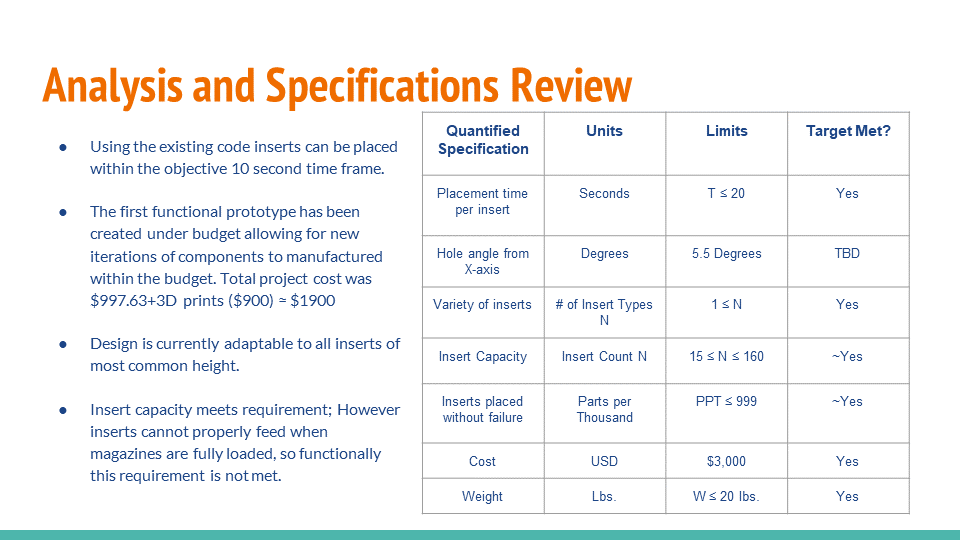

During the course of the project I completed all of the design work and fabrication necessary for the insert placement system to do its job. After part manufacturing everything assembled just as it was designed to. My other group members were Andrew La and Jonathan Bright. Andrew was in charge of electronic control systems and software. Jonathan was in charge of logistics, procurement, and record keeping. Our team poster, final presentation, quantified target specifications and a downloadable PDF of the project report are also shown below.